Transport at Nanoscale Interfaces

Nanomaterials Spectroscopy and Imaging

3D Printing

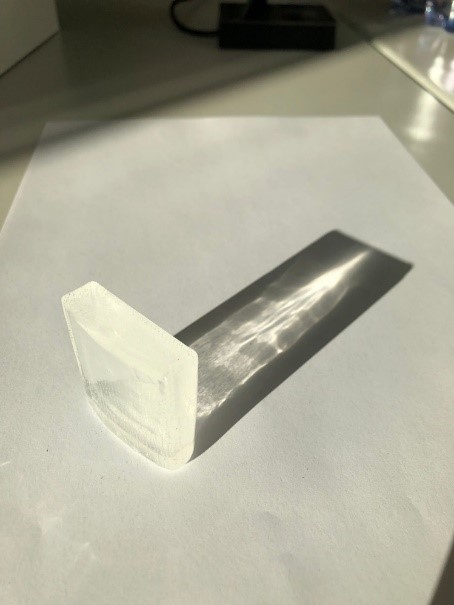

3D printing offers low cost and rapid development of materials. Our lab uses a 3D printer Kühling & Kühling RepRap Industrial and cyclic olefin copolymer (TOPAS) filament with diameter 2.85 mm from Creamelt for the 3D printing of various THz devices. TOPAS is transparent from UV up to 10 THz with low absorption, making it the ideal material for the 3D printing of THz devices. Using TOPAS, we 3D print devices such as waveguides, lenses, and microfluidic devices. For the 3D printing, we can improve the 3D printing quality using the following parameters: the 3D printing infill, printing speed, bed and chamber temperature, and nozzle diameter. Fig. 1 shows the results before and after optimization of the 3D printing with TOPAS. The goal of the project is to produce devices transparent at the same time in the VIS, IR, THz

Fig.1. Results before and after 3D printing optimization.

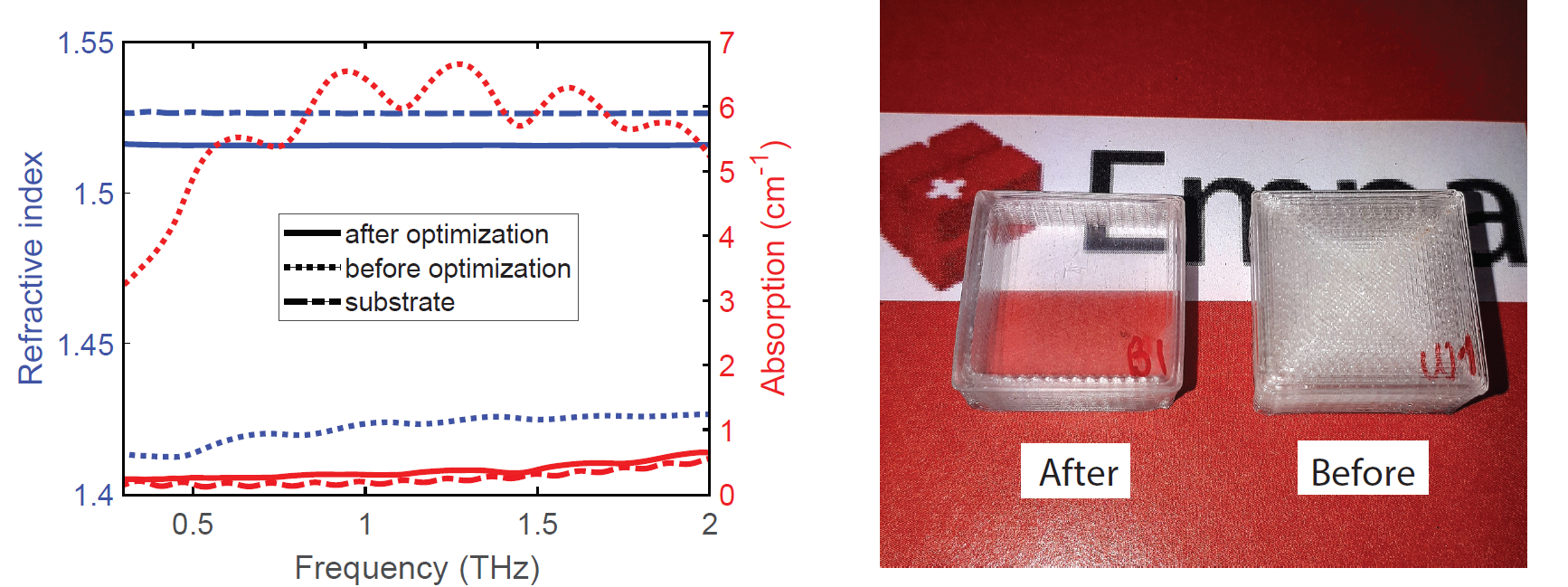

THz Waveguides (project 3D-TeraWaSp):

Fig.2. 3D printed THz pipe waveguide

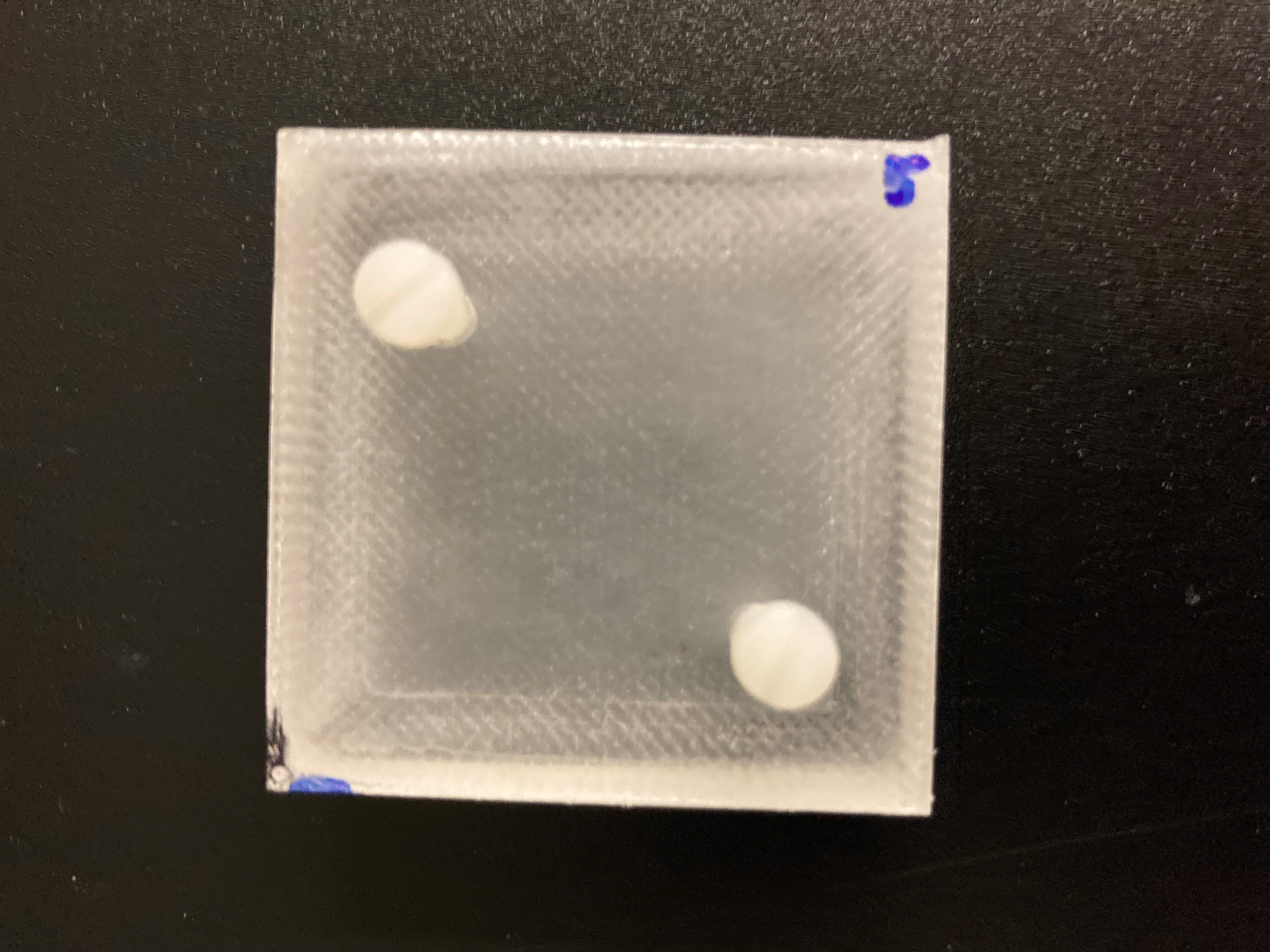

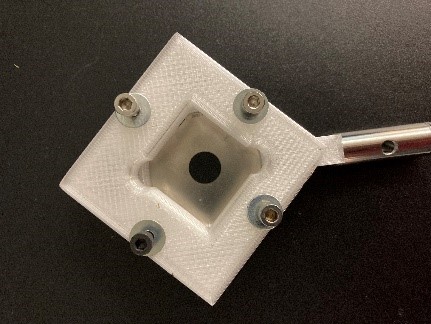

THz Microfluidic devices:

The microfluidic devices are used to characterize a variety of materials in solution in the THz regime. For example, we have characterized proteins (figure 3), and they can be used to characterize other materials such as nanoparticles, polymers, etc.

Fig. 3. 3D printed microfluidic devices and a 3D printed holder for the THz measurements of the devices. The holder ensures that we always measure the same area and better reproducibility of the measurements/results.

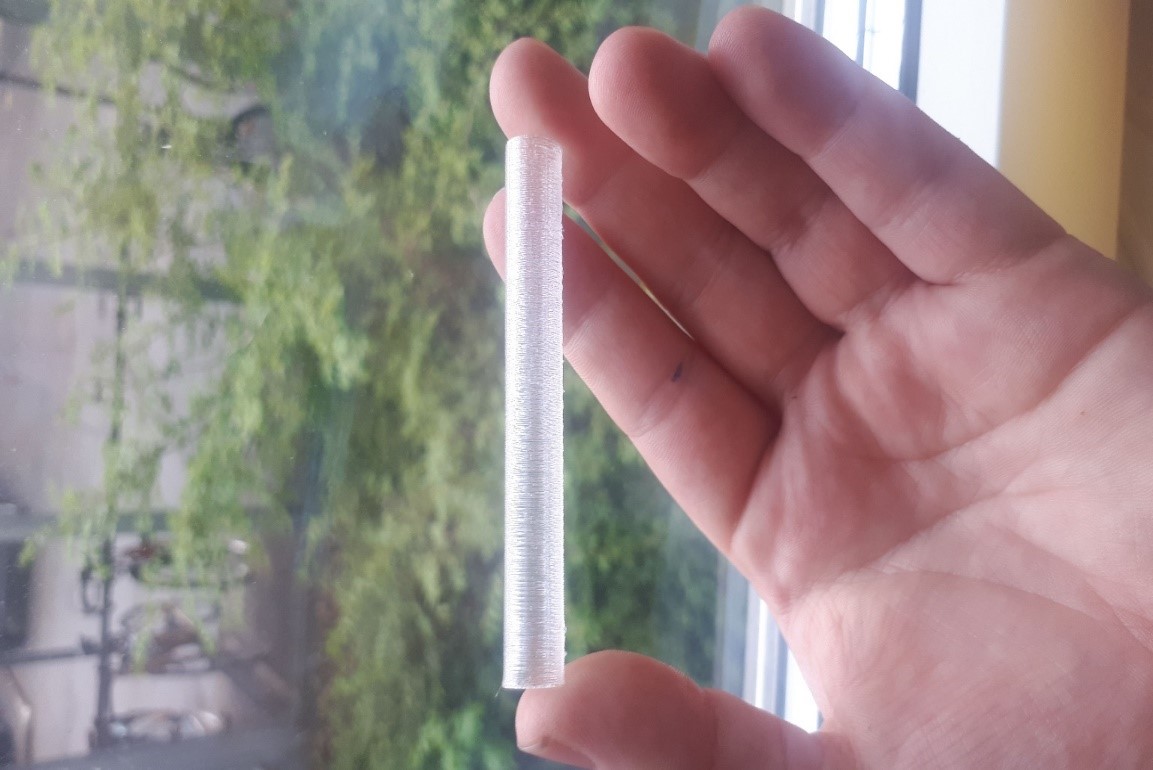

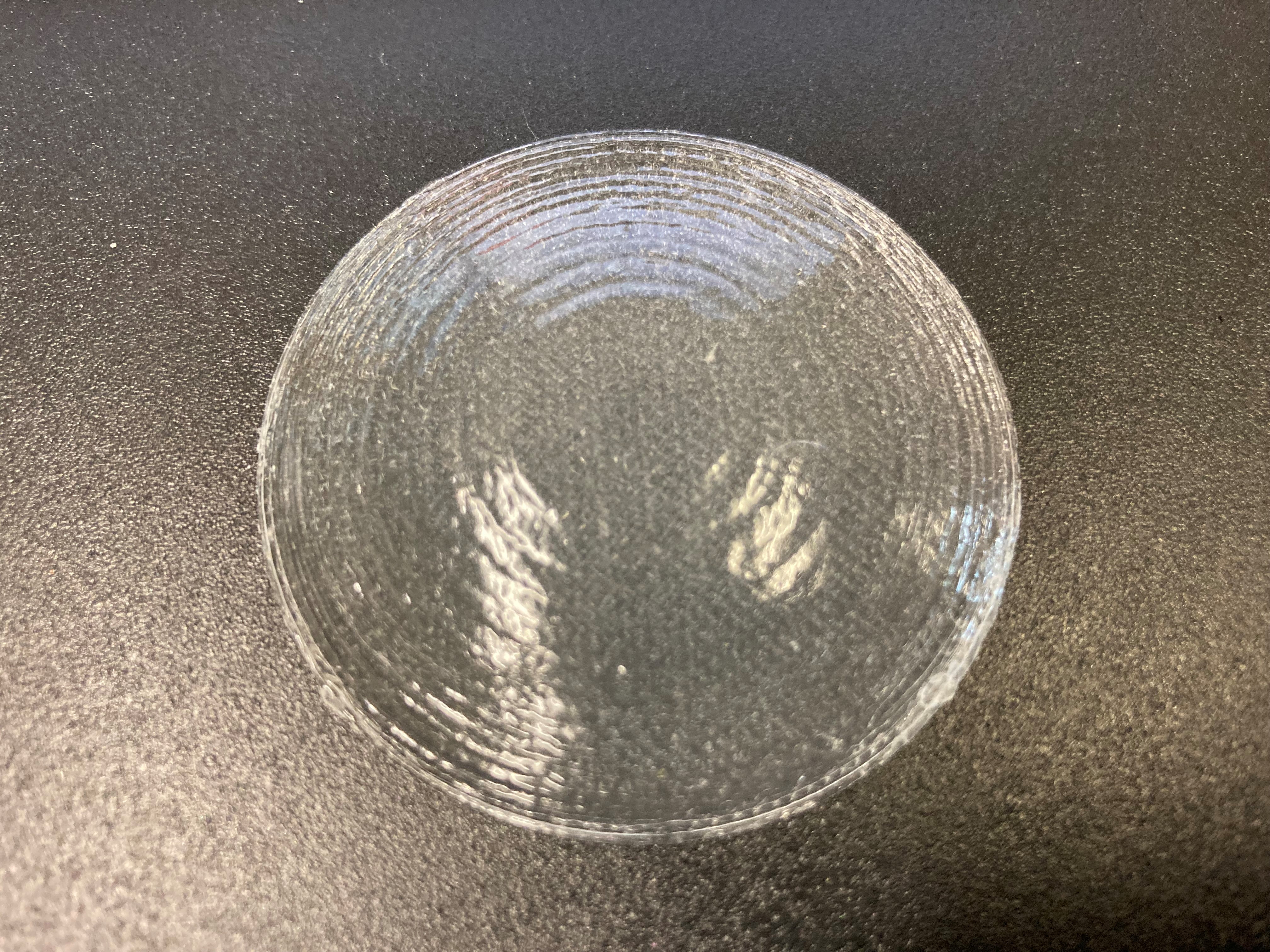

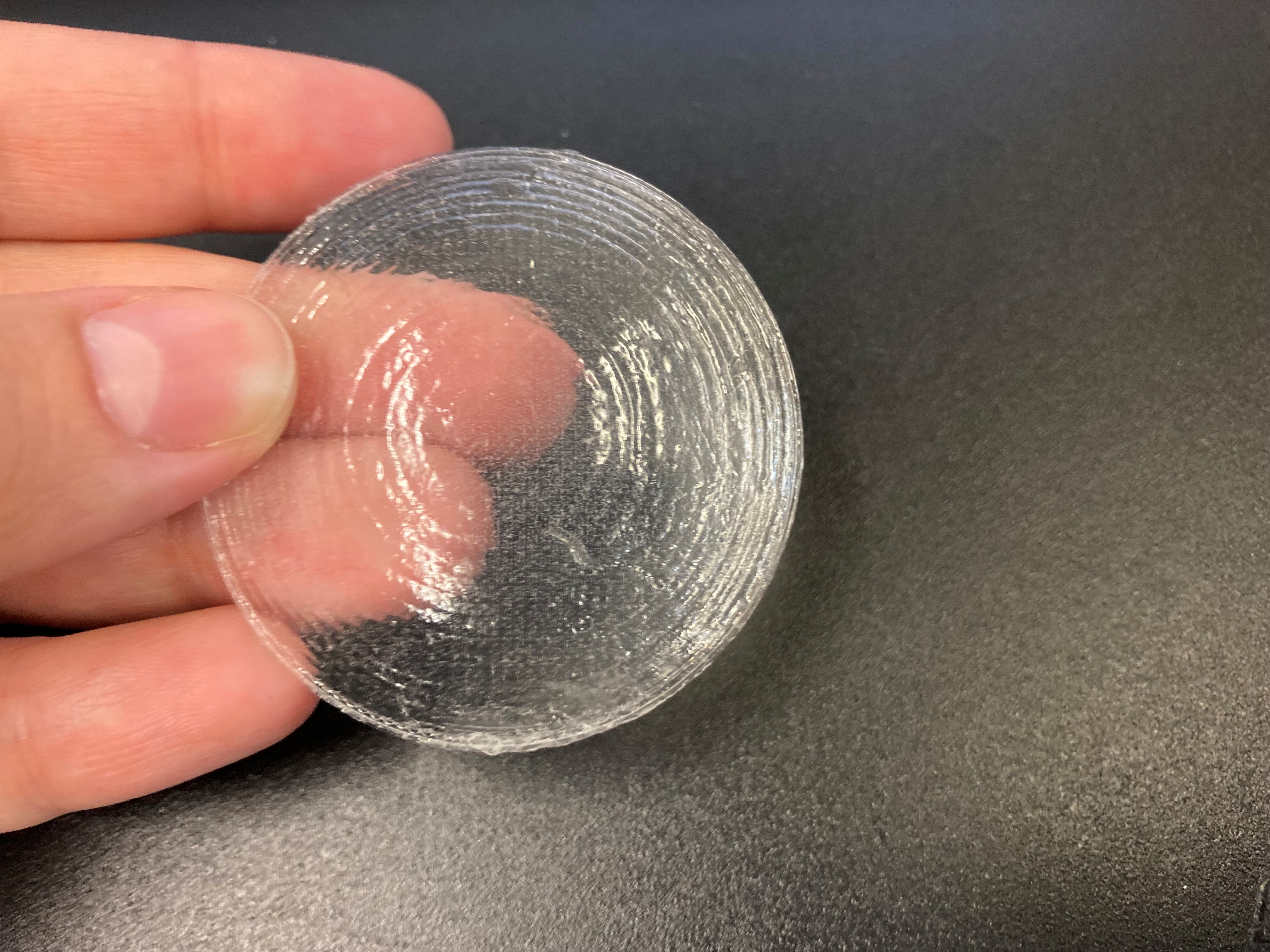

Lenses:

Lenses with focal length f=100 mm have 3D printed, and also cylindrical lenses have been printed.

Fig.4. 3D printing of simple lenses with f=100 mm.